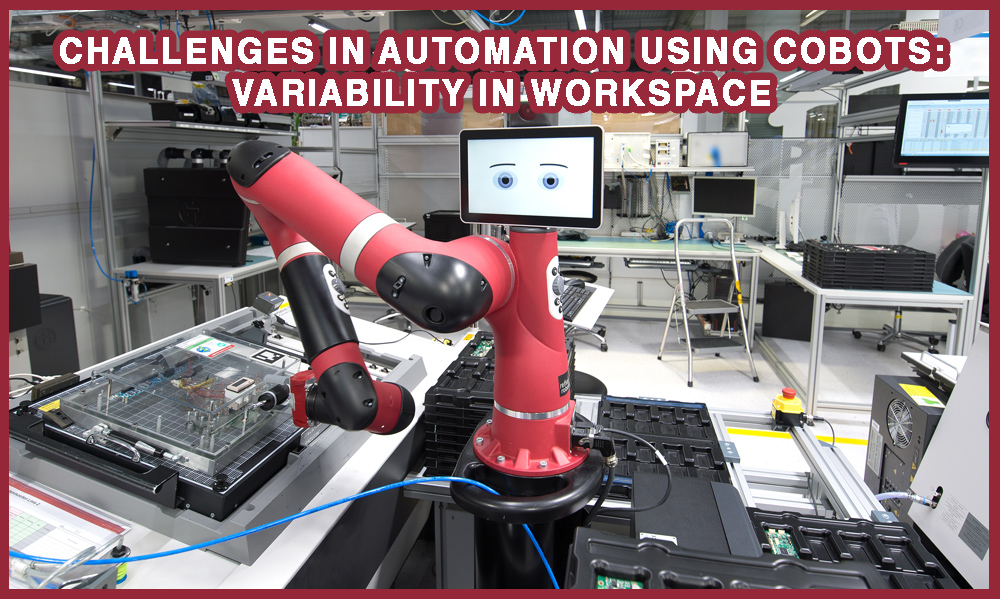

Cobots are gaining popularity in the industry thanks to their seamless ability to work 24 hours a day 365 days a week, and the best part, around other human operators without the need of a cage. These robots are robust and light and can be moved from place to place depending on the company’s needs for deployment. But what is the challenge in deploying cobots?

Variability in operations and workspace is one of the biggest issued faced by automation engineers in the cobot industry. Even though these robots have the physical capability to do almost anything humans can, they have to be programmed to perform these tasks. Since most of the tasks that the cobots are taking over are repetitive jobs currently being performed by human operators, most of these operations have a lot of variability in them. These variations are minor for humans but can be a major problem for the repeatability of cobots.

Automation applications require the workplace station setting to be as consistent and as automation friendly as possible to allow the robot to repeatedly perform the same series of tasks over and over again. Engineers usually anticipate and plan for any deviations from the norms and program these robots to be “smart”, but a conscious effort needs to be made to reduce this variation as much as possible. Flexibility in making minor changes and modifications in these operations is sometimes necessary to make the task repeatable so the robot can keep functioning indefinitely without any problems.