How Robotics is Revolutionizing Assembly

Until now, it has been impractical to automate certain assembly tasks with industrial robots. Fanuc has revolutionized the collaborative robot industry by making automation possible in a wider range of industry applications.

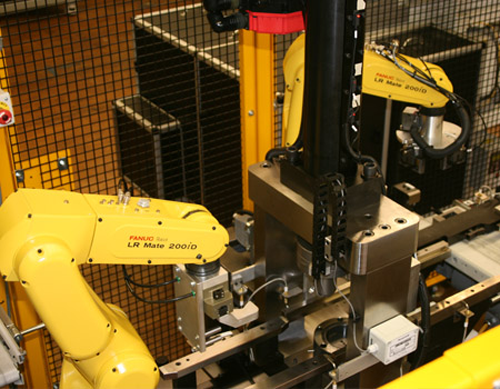

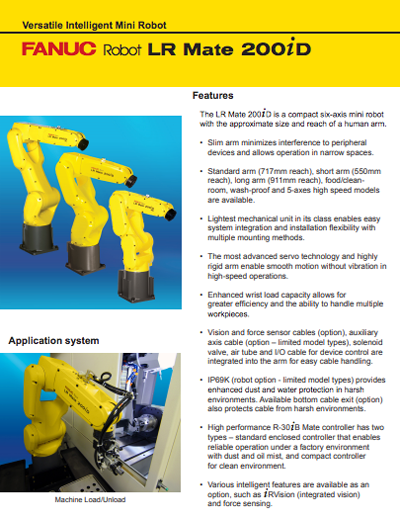

- Tight space capable: Fanuc has many robots to fit this need but the LR Mate series is a six-axis mini robot with the approximate size and reach of the human arm. Because of this, the LR Mate series can also operate in spaces designed for human workers, which means that this robot does not require you to make changes to your assembly line.

- Diversity in tasks: These robots can perform a wide variety of assembly tasks. With a variety of end effectors available, these robots can be equipped with end effectors that are perfect for every task such as metal fabrication, molding, packaging, line loading, and many more are available.

- Works with Variety of Materials: Equipped with numerous options for end effectors, these robots can work with many different types of materials including glass, metal, plastic, electronics, and wood.

- Increases Productivity: LR Mate is a relentless robot; it will never get tired, need to take a lunch break, get sick or need Holidays off. Able to work 24/7 and perform multiple assembly tasks in a row, this robot ensures your assembly line is always running.

- Safe for employees: Fanuc’s COBOT series can work safely in the same space as its human counterparts. With built-in force sensors, collaborative robots can make real-time, adaptive decisions while performing tasks. This collaborative robot works precisely, +/- 1 mm, ensuring the safety of surrounding workers.