Robotics can build your business in ways you never thought possible

Robots have forever transformed the way industries develop and manufacture products. Throughout the world, FANUC robots are used in factories to improve quality, increase capacity and overcome skills shortages. Robots have the capacity to create products that are too difficult or intricate for human assembly. Robotic technologies are also necessary when preparing pharmaceuticals in aseptic conditions and to protect workers from dangerous or harmful environments. Automated robotic systems can provide manufacturing advantages in all industries.

The complexity of robotic systems requires a thorough understanding of industrial robotics technology and real-world integration experience. RG Group understands this complexity and has worked with FANUC to build some of the most sophisticated and productive robots in the world.

About FANUC

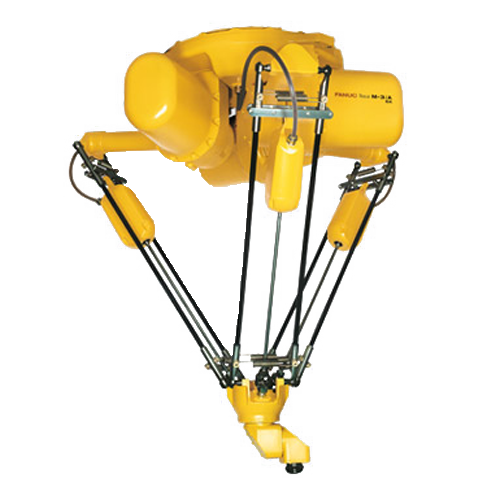

As an automation company, FANUC specializes in creating advanced robotic arms for manufacturing. These robots feature state-of-the-art technology including 3D Vision systems for sensing. The advanced attributes allow FANUC robots to complete various types of manufacturing tasks. Through the creation of more than 100 robot models, FANUC has developed robotic technologies to satisfy every task. Whether it’s a huge machine with long-reach and massive payload capabilities or a compact articulated robot, manufacturing needs can be matched. Task options include high-speed Delta robots and painting robots. FANUC also has an unguarded option known as the CR-35iA collaborative robot.

FANUC Integration

Utilizing a robot in a manufacturing setting requires interfacing it with other production equipment, including intake and output conveyors and handling devices. The robot also needs a hand or gripper at the end of the arm. This gripper is used to pick up small parts and other tools such as welding torches and spray guns. Implementing these components is the duty of the integrator, and in many cases, the expertise of the integrator dictates the difference between success and failure.

The RG Group Edge

In the United States, RG Group has partnered with FANUC to integrate their industrial robot lines. Headquartered in York, PA, RG Group is a distribution and manufacturing company. RG Group is ISO-certified in manufacturing services. This certification gives companies that collaborate with RG a competitive advantage. RG Group has been responsible for providing leadership in the design and delivery of innovative motion control and fluid handling products and solutions for more than 60 years.

Hardware knowledge and programming skills are only the primary components of successful robot integration. Integrators must also have the intuitive skills to create solution-driven robotics. This process begins by defining requirements and creating solutions based on a wide range of experiences to suggest and evaluate options. The design work can then begin. The project management process must be rigorous to ensure each milestone is reached on time. Leading integration experts, like RG Group, make sure that automation components communicate effectively.

ARC Mate

Collaborative Robot

LR Mate Series

M-1iA Series

M-2iA Series

M-3iA Series

M-10 Series

M-20 Series

M-410 Series

M-710iC Series

M-900 Series

M-2000iA Series

Paint Robots

R-1000iA

F-200iB

R-2000 SEries

SR SCARA Series

See the world of opportunities that FANUC robots give you.

We take pride in our quality relationships built in trust.

RG Group provides high-quality robots, systems and parts to companies big and small. Our goal is to see our customers thrive in the manufacturing industry by offering cost-effective robotic automation solutions.

RG Group is an Authorized System Integrator for FANUC Robotics America, Inc. Our partnership allows us direct access to manufacturer resources to provide our customers complete and knowledgeable expertise.