With international spending on robotics soon to reach over $100 billion, it’s clear that there are some major changes coming to every industry. Industrial robotics has a lot of potential productivity, innovation, and financial benefits that are just waiting to be unlocked through research in the field.

If you’re interested in finding out how your facility could benefit, you need to learn what’s being done in the industry.

Here are just five of the ways that industry is slated to change with the help of robotics and what it has to offer.

1. Work Safely In Harsh Environments

If you’re looking to limit the amount of human work that’s happening in hazardous environments, industrial robotics provides some powerful solutions. Manufacturing jobs that include the production of heavy objects and use of toxic chemicals is a challenge that robotics can handle.

When you take away some of the hazards, you make it easier for people to work comfortably in environments they wouldn’t normally be comfortable.

This ends up being attractive to higher level executives because it preserves and protects the company’s reputation. It also lowers the legal liability that they can find themselves in. When working in riskier environments, it’s vital to be able to save money on insurance and legal fees whenever possible.

Many mining operations and large production sites are using robotics whenever possible. By keeping their engineers and workers out of harm’s way, they replace unskilled dangerous labor with something that’s much better for everyone.

2. Expect Efficiency

When you’re working with robotics, you can complete many of the most common tasks on a worksite much faster. So much of the work that needs to be done by people at an industrial work site is repetitive and taxing on the body of workers.

Over time, fatigue causes workers to become tired and make mistakes, which costs money.

If you want to improve production on your line or work with fewer mistakes, allowing your workers to manage robotic workers can help. They’ll be able to do repetitive tasks without the bodily fatigue that can impact their decision-making.

Robotic workers save you money in time and resources which can be put into other elements of your work. You can ensure that your workers receive better training and that you use the best tools when you’re able to get more done in a day.

The quality of work that robotic workers can provide is another side effect of better efficiency. Your robotic workers can provide a higher quality of products and services and adhere to superhuman standards of quality.

3. Profitability Skyrockets

When you take away the danger, take away the fatigue, and add in superhuman levels of accuracy, you see a growth in profits. When you can produce more in a shorter period of time, you’ll end up with a higher degree of profit. You get to divert staff into other aspects of your business as well.

You can remove some of the staff that you’d normally have on the ground working at the level of production.

You can replace them with workers who are focused on marketing your products and connecting with vendors, customers, or clients.

When you produce more with a higher degree of quality control, you end up spending less per product. This provides you with the chance to expand your services beyond the current base that you’re serving. You can take more risks when you have more money to play around with.

4. Expand Working Hours

At your current site, you could be running a 9-5 operation where you get the most productivity during a few key hours in the day. No human being can work at 100% for 8 full hours every single day. When you have robotics on your side, you can do this.

If you can get robots to work 24 hours a day, you can have your company producing three times as much product as before. You’ll outpace all of your human staffers with a production line that works harder than any human could.

So long as you have people on site to maintain your robotics properly, you can ensure that you keep running at a powerful pace.

Your robots are never going to need a holiday off, time off for illness, or a break.

Run them properly and you could have a workforce that gives you more than you ever thought you could get.

5. Serious Tech Prestige

When you employ robotics as part of your production team, you can name yourself as a trendsetter. You can tell investors how you’re at the cutting edge of the industry, because you are.

This brings in more money, which also brings with it more customer and client faith.

A non-robotic system might work for some companies, but you can turn your robotics into a marketing tool. You can use it to boost your brand and give something special to PR for them to use. You’ll end up seeing more benefits than you’d ever imagined.

Everyone wants to work with the most high-tech company on the block. When you can do things that other companies can’t, thanks to industrial robotics, you’ll win clients you never thought you’d be able to.

Automation makes you look good.

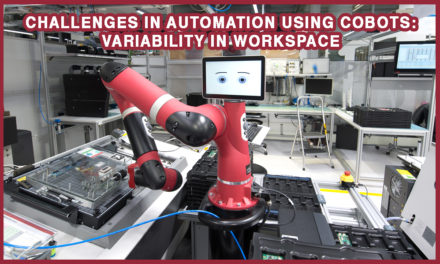

Industrial Robotics is More Than Just Robot Arms

Because of the way that machine learning and artificial intelligence is feeding into the industry, industrial robotics has room to grow. The potential for change in industrial robots is going to make the whole world of industry change.

For more about how collaborative robots could help you at work, check out our latest guide.