Collaborative Robotics will be taking the world by storm within a few years’ time, but whether or not they will be beneficial to the world will only be answered in time.

Since the 1990s, collaborative robots, also known as cobots, have been a part of society, but in the recent advancements, the profile of cobots has grown substantially along with the automation and sensor technologies and artificial intelligence.

The massive debates surrounding cobots is not likely to die down soon, and they are either about to become the natural progression of the workforce or they are going to devastate the workforce by eliminating these skilled labor jobs. Depending on who you question, either idea is likely to come up in the discussion. The legislators of the European Union along with the founder of Microsoft, Bill Gates, have suggested the idea of putting a tax on the robots to make up for the tax revenue that will be lost when replacing the human workers. There has even been recent talk during the World Government Summit about robotic automation reaching a point where the only way humans can maintain the standard of living will be to obtain a universal basic income, meaning the government will be giving each citizen a base-level income.

No matter where you sit on the debate, there is no denying that the cobot revolution is growing each day. Reports from 2016 show that the market for collaborative robots will grow to almost $3.3 billion by the year 2020 through the automotive, metal, machining, furniture, plastic, polymer, equipment, and food industries. The research also shows the number of safety concerns that are one reason why cobots are becoming the main push for their adoption.

When it comes to the collaborative robots business, there are many companies that are increasing their product as the cobots become more mainstream. Here are the ten best collaborative robotics companies that everyone should keep their eyes on in the future.

Vecna

Focusing on the robotics automation, Vecna is essentially an end-to-end company that produces product solutions in areas like warehousing, omnichannel order fulfilling, and manufacturing. Instead of focusing on the robot platform, they take a different approach to optimize workflow through an artificial intelligence approach. Venca’s robots not only use the computer vision for recognition, but they use the computer vision for navigation as well. The sensor-fusion technology on the robots has mapping and localizing skills called SLAM. This is the same technology that autonomous cars employ, and the cobots use this technology to understand the three dimensions of the workplace to navigate it adequately.

Robotiq

A unique entity in the world of cobotics, Robotiq creates tools that robots use instead of creating their line of robots. Their most famous line is the Universal Robots’ UR. Robotiq makes a series of add-ons that make it easy to augment the robot’s arm functionality, just by simply plugging the products in. The company has at least four different flagship products to their name: a robotic hand with three fingers, adaptive grippers with two fingers, a sensor with force touch that gives touch-sense capabilities to the robots, and a camera vision system for that needed object recognition. Companies who are looking to implement these cobots at a faster rate can take a peek at Robotiq’s custom program templates, which is useful for many of the common applications.

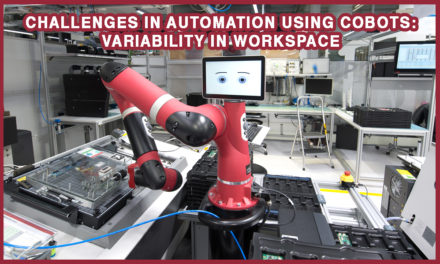

Rethink Robotics

One of the most well-known companies in collaborative robotics is Rethink Robotics. They have turned heads for the past few years with their flagship product, Baxter. This friendly looking robot is made to target the monotonous and dangerous tasks on the shop floor. The company has recently added a new robot to the mix, called Sawyer. Each of these robots specializes by using a force-sensing technology to maintain the safety of the working environment while being right beside the human workers. Through the company’s Intera software, the robots are trained to their specific tasks, nor programmed. The skilled worker will walk either robot through their tasks, and the robot will learn the task and repeat it in real time. Rethink is also working to expand their products and offerings within a more specific area. This area is dedicated to robotic grippers. The ClickSmart toolkit, which is the first expansion, is being put in place to help their robots adjust to broad handling or even delicate tasks in the workplace. The grippers have a specific swapping capability that is rapid, and they are designed to make the adoption of cobots easier for many different companies, even if the companies are unsure whether the Sawyer or Baxter robots cannot handle their automation tasks.

Universal Robots

UR3, UR5, and UR 10 are three of the major collaborative robot arms that Universal Robots works to manufacture. This company has a wide variety of applications that include things like place, pick, quality inspection, injection molding, assembly, palletizing, and packaging. The UR series is created to be trained manually through specific movements of the arms. The UR series has even been deployed worldwide to major companies like Nissan, Yokohama, and more. The robots give each company the chance to train more workers and to bring relief when workers are stuck handling repetitive tasks. Universal Robots even uses its own robots to help manufacture the robots being dispersed.

ABB Inc.

ABB, located in Switzerland, has what is considered the be the first collaborative robot in the entire world. The YuMi Robot is targeted at automating those tasks that are a part of the consumer electronics industry. Recently, the company has announced that a collaboration with IBM will be put in place to leverage their Thingscomputing capabilities, more specifically the Cognitive Visual Inspection tools. Using Watson’s image capabilities for recognition will enable the companies to use the ABB robots for inspection tasks. This includes detecting flaws that a human might miss. Computer vision also enables the YuMi robot to gather a set of visual data to understand the tasks at hand and take action to reduce any inefficiencies in the work or redundancies.

Fanuc

Back in 2015, Fanuc put their option in the game with the release of the CR-35iA, which is a 6-axis robot that is targeted toward the dangerous or monotonous tasks. The collaborative robot is only about 77 pounds, and it is designed to work right with humans without a cage or even fencing. This robot handles the difficult tasks that might be dangerous for humans to do, and it comes to a halt gently if it ever bumps into a human. Fanuc has even added a second layer of safety to the robot through their special green foam coating. The company notes that the robot maintains contact of less than a normal 150 N.

Omron

Many companies worldwide focus their cobots on a fixed workspace, but Omron has something else in the store. Their cobots are made for mobile robotics solutions, meaning that the robots can move around and navigate around workspaces or factories just as easy as a human worker. The Lynx robot, which was released early this year, is designed for the transport of materials in factories, hospitals, warehouse environments where it is often difficult for humans to move efficiently. The robot uses a self-navigating system to adjust and build maps of the work area, and then it uses these maps to determine the most efficient routes to take in the workspace. The robot can be trained through a human worker walking it through the space to teach the robot the layout of the workspace.

Festo

Festo is better known in society as an electromechanical and pneumatic systems manufacturer, but in the last ten years, the company has launched a certain initiative to develop different products within the collaborative robotics space. The Bionic Learning Network, or the BLN, is the company’s new effort to help develop these industrial robots. How? They intend to do this by finding inspiration from nature. The collaborative efforts with both universities and students along with companies is the process by which Festo intends to develop three different products: The BionicCobot, BionicMotionRobot, and the OctopusGripper. These robots are virtually lightweight like the human arm, an elephant’s trunk, and an octopus’ tentacles, and they are created to mimic the movements like these inspirations right alongside the human workers and in small environments. The BionicCobot, specifically, uses a seven-joint system to mimic the functionality of a human arm, which includes the functions of the muscles like the biceps and triceps. The BionicMotionRobot mimics an elephant’s trunk as well as an octopus’ tentacles, similar to the same motions of the OctopusGripper option.

Locus Robotics

You might not consider an e-commerce fulfillment company to be a robotics company as well, but they are in this case. Locus Robotics is such a company that uses robotics to focus on an improved labor productive in the warehouses throughout the world. They use cobots to help get the job done. April brought about a new unveiling of the Locus Robotics Advanced Navigation, or LRAN, software to help coordinate the multiple robots within a factory environment. Typical challenges of deploying multiple sets of robots within a warehouse environment including things like creating safety hazards or traffic jams. The LRAN software, which is a cloud-distributed option, was created by Locus to aim toward optimizing the robots and their navigation performance and accuracy within the workplace.

Epson Robots

A manufacturer of cobots for mother material handling and assembly, Epson Robots disperses their robots to places like aerospace, electronics, automotive, medical devices, and consumer product industries. February brought about a release of a brand new series of robots that are compact and made with a 6-axis. These robots, called the Flexion N-Series, is designed for smaller workplaces. The Flexion robots fold themselves instead of moving around itself. This produces a smaller footprint over traditional 6-axis robots. Epson has added a proprietary technology that is vibration-reduction to the robots to help with precise tasks and the handling of delicate pieces of objects.

Conclusion

When it comes to automation through robotics and collaborative robotics in the workplace, it is becoming a more common occurrence as the years go by. The automation of the workplace might be a negative to some, but the implementation of these cobots is great in many ways to help reduce struggle in the workplace and even reduce the number of safety hazards. In the future, these cobots will be rising in number as many warehouses, hospitals, and factories begin to add them to their workforce to help add training time for their human employees, eliminate safety hazards for difficult jobs, and even give the human employees a chance to rest during the workday by giving human employees a break. Cobots will be a normal part of society within the next few years, and it might not be as bad as people think.